MAXX MODEL ME PRO CNC Hopup unit for M4 AEG

€69.90

Out of stock

Description

Product Description

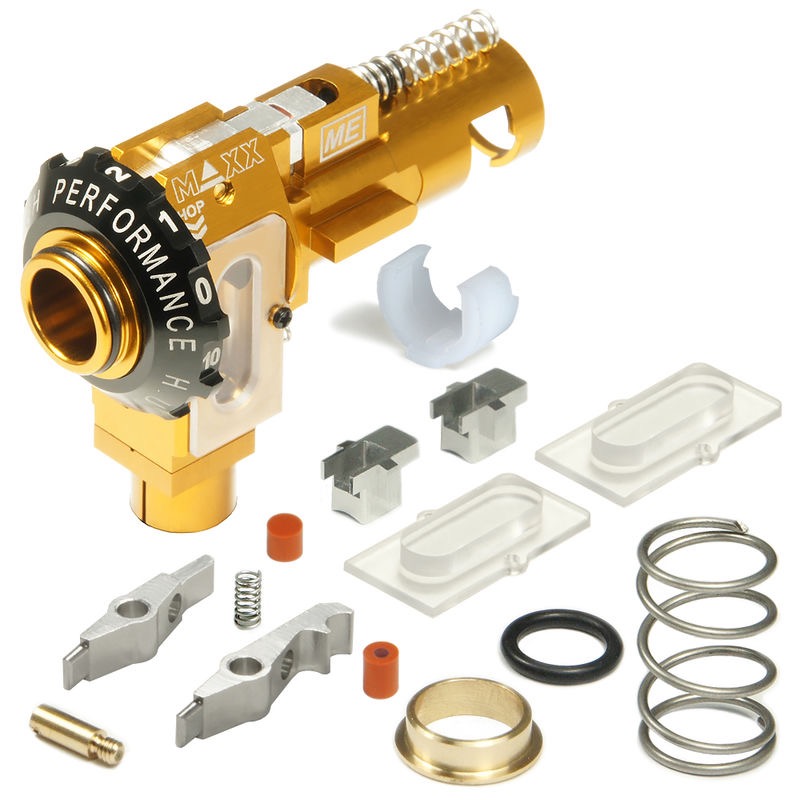

CNC Aluminum Hopup Chamber ME Pro (with BB Latching System) is precisely made to improve accuracy and ensure consistent air seal for Tokyo Marui (include KRYTAC, except KWA) M4/M16 Standard AEG series.

The Hopup Chamber ME unit has a precision rotary dial design for fine hopup adjustments, also re-engineered the hopup levers and concave nubs to work best with R-hop and Standard-Hop to keep the BBs shooting straight and accurate on every single shot.

The Hopup Chamber ME unit is designed to accept the nozzle length from 21.00mm to 21.25mm, and fully compatible with most aftermarket soft and hard rubber bucking without losing FPS or dropping BBs.

The Hopup Chamber ME Housing is equipped with a new CNC Delrin Locking C-Clip design to hold barrel tight without wobbling and twisting, and 3 compression springs on top, at bottom and in center of housing to ensure the hopup unit is exactly centered, straight and air tight at all times when adapted to any V2 gear boxes with 11mm or 11.5mm inner bore.

More than that, the Hopup Chamber ME Pro unit is specially designed with BB Latching System to prevent dropping BBs after removing the magazine. The Latching System can be also manually opened to release BBs from inside hopup chamber by hand.

***The Empty Magazine Detection Sensor and Electronic Switch Controller are optional add-ons to stop Motor/HPA firing when the magazine is empty. (Sold separately)

***Test results: FPS might be increased from 10FPS to 30FPS over stock setup. Please check your FPS!

| Includes | |

| 1 x CNC Aluminum Hopup Chamber ME Pro (with BB Latching System) unit | |

| 2 x Strong Clear Vinyl Cover set | |

| 1 x CNC Aluminum Standard-Hop Arm | |

| 1 x CNC Aluminum R-Hop Arm | |

| 1 x Silicone Rubber Standard-Hop Nub Damper | |

| 1 x Silicone Rubber R-Hop Nub Damper | |

| 1 x CNC Aluminum 4.5mm length Precision R-Hop Concave Nub | |

| 1 x CNC Aluminum 6mm length Precision R-Hop Concave Nub | |

| 1 x CNC Brass Threaded Slot Pin | |

| 1 x CNC Delrin Locking C-Clip | |

| 1 x CNC Barrel Brass Spacer | |

| 1 x Brass Spacer Holder Oring | |

| 3 x Steel Compression Spring |

| Specification |

| Overall Length: 51mm | |

| Overall Height: 37.75mm | |

| Hub Outer Diameter (to fit into Gear Box): min 11mm – max 11.5mm | |

| Hub Outer Diameter (to fit into Outer Barrel): min 12mm | |

| Hub Inner Diameter (to fit Nozzle): max 8.3mm | |

| Feeder Outer Diameter (to fit magazine): min 9.25mm | |

| Feeder Length (to fit magazine): max 6.25mm | |

| Material: Aluminum 6061 |

| Features | |

| Machined from a solid aircraft aluminum block with tight tolerances to provide better accuracy, consistency, and durability | |

| Improved accuracy and ensure consistent air seal for Tokyo Marui (include KRYTAC, except KWA) M4/M16 Standard AEG series | |

| Precision rotary dial design for fine hopup adjustments | |

| Re-engineered the hopup levers and concave nubs to work best with R-hop and Standard-Hop to keep the BBs shooting straight and accurate on every single shot | |

| Removable Brass Threaded Slot Pin for setup and maintenance | |

| Accepted the nozzle length from 21.00mm to 21.25mm | |

| Fully compatible with most aftermarket soft and hard rubber bucking without losing FPS or dropping BBs | |

| Equipped with a new CNC Delrin Locking C-Clip design to hold barrel tight without wobbling and twisting | |

| Equipped with 3 compression springs on top, at bottom and in center of housing to ensure the hopup unit is exactly centered, straight and air tight | |

| Compatible with any V2 gear boxes with 11mm or 11.5mm bore | |

| Specially designed with BB Latching System to prevent dropping BBs after removing the magazine | |

| Manually opened to release BBs from inside hopup chamber by hand | |

| The Empty Magazine Detection Sensor to stop Motor/HPA firing ready! |

| Weight | |

| N/A grams |

| Usage | |

| Compatible with most Tokyo Marui (include KRYTAC, except KWA) M4/M16 standard AEG version 2 gear box |

| Requires | |

| Wearing eye protection is recommended | |

| Use proper tools for disassembly and reassembly the gear box with great care due to spring tension | |

| Bearing lubricant oil/grease is recommended for smooth operation |

| Instruction | |

| Instruction Manuals are included |

Reviews

There are no reviews yet.